Urea SNCR Flue Gas Denitrification Project In Coal Power Plant

Product Details:

| Place of Origin: | China |

| Brand Name: | SINOCHEM |

| Certification: | GB/T2440-2017 |

| Model Number: | 50kg |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100t |

|---|---|

| Price: | USD460 |

| Packaging Details: | bagged |

| Delivery Time: | 7 days |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 4000000 t/year |

|

Detail Information |

|||

| Product: | Urea | Class: | Qualified |

|---|---|---|---|

| Nitrogen Content: | ≥%46.0 | Biuret Content: | ≤%1.0 |

| Moisture Content (H2O): | ≤%0.7 | Iron Content(Fe): | ≤%0.001 |

| Alkalinity(NH3): | ≤%0.03 | Granularity(0.85-8mm): | ≥%90 |

| Water Insoluble Content: | ≤%0.04 | Sulfate Content(SO42-): | ≤%0.02 |

| High Light: | Coal Power Plant Urea Contains Nitrogen,Chemical Urea Nitrogen Fertilizer,Loose Urea Fertilizer |

||

Product Description

Urea solution for denitrification in coal fired power plant

Urea, also known as carbamide, is an organic compound with chemical formula CO(NH2)2. This amide has two –NH2 groups joined by a carbonyl (C=O) functional group. ... Urea is widely used in fertilizers as a source of nitrogen (N) and is an important raw material for the chemical industry.

Because of the safety in transport and storage denitrification technology with urea serving as reducing agent has attracted more and more attention.

Generally speaking, denitration is to spray ammonia or urea solution into the furnace after atomization to remove nitrate (i.e)Nitrogen oxides (mainly nitric oxide and nitrogen dioxide) are removed from the flue gas and become harmless to the air technology, namely selective non catalytic reduction technology, is one of the main flue gas denitration technologies at present different reducing agents have different reaction temperature ranges,this temperature range is called the temperature window. When the reaction temperature is too high at high temperature, due to the decomposition of ammonia, the NOx the reduction rate decreases. On the other hand, when the reaction temperature is too low, ammonia escapes The increase of fugacity will also make NOx Reduced reduction rate. SNCR The key of the process technology lies in the reductant injection system

The reducing agent must be injected into the most effective temperature window area in the furnace as far as possible, That is, ensure the spraying as much as possible the added reducing agent is well mixed with the flue gas at an appropriate temperature, on the one hand, the reducing agent can be improved on the other hand, smaller ammonia escape can be controlled.

This set of denitration equipment includes metering pump station system (metering pump, pressure gauge, pipe fittings, valves, base and electric control box)

Denitration spray gun (nozzle, gun rod, protective sleeve, mixer, quick connector, quick release clip, etc.) (urea solution pipeline, compressed air pipeline)

Urea solution preparation system

1. The advantage of urea solution as denitration reducing agent is clean, hygienic and safe.

2. In winter, it is usually prepared to a concentration of 10%. In this project, the volume of the mixing tank is 2 cubic meters, and 4 bags of 50kg urea can be put. In summer, it is possible to prepare more concentrated (15-20%) and reduce the flow of the metering pump accordingly. When the boiler load is relatively large, the concentration can be larger.

3. Agricultural urea particles can be used for urea, and high-quality urea with standard nitrogen content is better.

4. Urea is very easy to absorb water, damp and harden, so it should be placed on a wooden support and kept dry during storage improve air circulation

5. Urea soluble particles absorb a lot of heat during dissolution, so try to use hot water or water when preparing urea solution

Steam shall be introduced to prevent the urea solution from crystallizing at low temperature and blocking the pipeline or spray gun.

6. Softened water or demineralized water shall be used to prepare urea solution to prevent crystal scaling from blocking the nozzle.

7. Always check the liquid level of mixing tank and storage tank and prepare in time to prevent the transfer pump and metering pump from being empty Water transport.

8. After the urea transfer pump has pumped out the solution in the mixing tank, add an appropriate amount of clean water in the mixing tank to continue pumping In the storage tank, the purpose is to clean the transfer pump to prevent urea from crystallizing in the mechanical seal of the pump.

9. The main reason why the transfer pump does not discharge water is that there is air in the pump, so it is necessary to open the vent hole to fill the solution Just pump.

10. Always open the filter and clean the filter screen. There are impurities in urea particles, and there are impurities in urea bags the proof paper, woven bag, plastic skin and sealing line shall be taken out to prevent blocking the filter.

Denitration metering system

Denitration metering system is the core and main equipment of SNCR denitration equipment. Its main function is to accurately measure the flow of urea solution.

1. The metering of this module is mainly regulated by electric regulating valve, and then measured by electromagnetic flowmeter.

2. In order to meet the needs of head, the urea solution delivery booster pump provides pressure for the pipeline system. The pressure is usually set at 0.4-0.5mpa. If the pressure is too high, the return valve can be adjusted to relieve the pressure and return. When the pressure adjustment is incorrect, the pipeline will have vibration and abnormal noise, which can be eliminated by regulating valve.

3. When the pressure of the delivery booster pump is low or there is no pressure at startup, check whether the storage tank is short of water or whether the filter in front of the pipeline of the pump station is blocked. (unscrew the cover of the Y-type filter to view and flush the filter screen)

4. At ordinary times, check whether the pipeline is running, emitting, dripping and leaking, and tighten the thread in time to prevent urea solution from exuding crystal white.

5. This module is equipped with two delivery booster pumps, one for use and one for standby. When a pump fails, switch to the standby pump.

Specification

| No | description | unit | standard |

| 1 | class | - | qualified |

| 2 | nitrogen content (dry basis) | % | ≥46.0 |

| 3 | Biuret content | % | ≤1.0 |

| 4 | Moisture content (H2O) | % | ≤0.7 |

| 5 | Iron content(Fe) | % | ≤0.001 |

| 6 | alkalinity(NH3) | % | ≤0.03 |

| 7 | Sulfate content(SO42-) | % | ≤0.02 |

| 8 | Water insoluble content | % | ≤0.04 |

| 9 | granularity(0.85-8mm) | % | ≥90 |

About us

Our company SSI is the representative of overseas markets of SINOCHEM FERTILIZER CO, LTD, which is a state company. Sinochem chemical fertilizer Holding Co., Ltd. (hereinafter referred to as Sinochem chemical fertilizer, formerly known as Sinochem Hong Kong Holding Co., Ltd.) is the largest fertilizer supplier and distribution service provider in China, covering the whole industrial chain of resources, R & D, production, distribution and agrochemical services

Qualify certificate

![]()

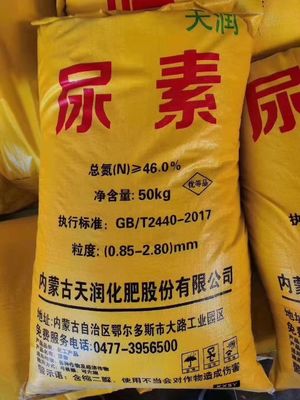

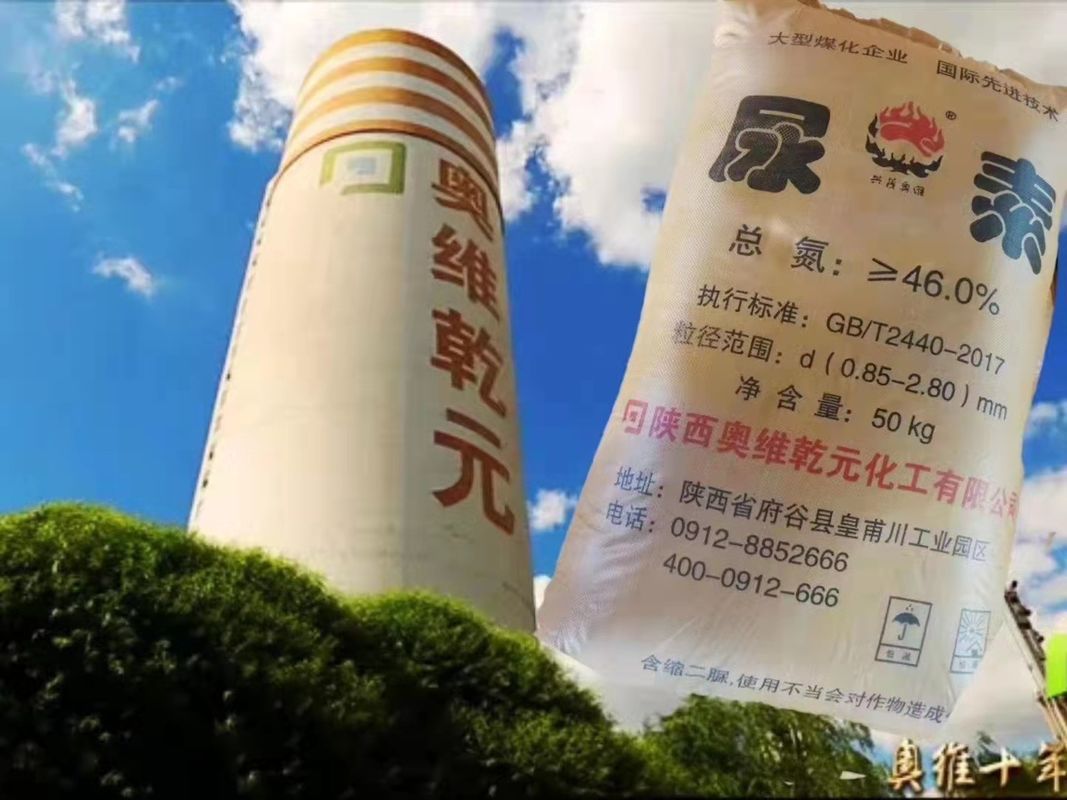

Photos of Urea

![]()

![]()